Everything is decided from DATA INPUT

Understanding the PUTAWAY strategy by using ABC analysis

For every warehouses want to pick up goods faster and increase the outbound productivity. The solution is the putaway strategy. Putaway and Picking are key processes in warehouse operations. Although they seem to be independent processes, the Putaway and Picking strategies are actually causally related. Today let's learn how to increase productivity through Putway strategy by applying ABC analysis

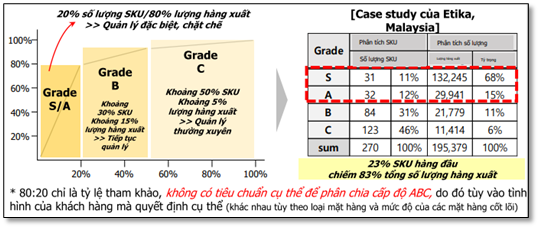

STEP1: Classification of stored goods by ABC analysis

What is ABC inventory management?

From the Pareto principle which explains that 80% of the total quantity of outbound is concentrated in the Top 20% "Fastest Moving SKU" (principle 8:2), the ABC method divides the total inventory into 3 categories A~C according to a certain value, thereby helping to divide different time and resources for each type of item in stock

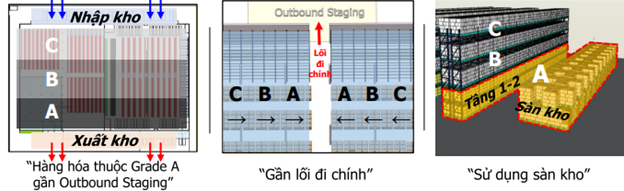

STEP 2: Rearrange goods in warehouse (re-location) based on ABC analysis

The key to reordering inventory is to reduce operational difficulty and shorten the travel distance of Grade A items. Maximize warehouse productivity by locating Grade A inventory – the goods category have largest contribution of throughput quantity - at the location easiest to touch

Source: Global Innpvation Team - CJ LOGISTICS