The retail market in Vietnam has welcomed many new players over the past seven years. It would be remiss not to mention Cycle K, GS25, 711, B'smart, Mini Stop, Bach Hoa Xanh, Winmart, among others. In the race for market share, retailers continue to expand their convenience store systems to different regions and use product diversification strategies to attract buyers. The faster the expansion, the more it demands quick and flexible responses from the supply chain. The pressure of managing inventories of thousands, or even tens of thousands of SKUs, dispersed store networks in different geographic areas, varying lead times for delivery, receiving and booking from suppliers, and many other complex factors can make retail logistics managers distressed.

At CJ Gemadept Logistics, we truly understand the anxiety and concerns of retailers, especially in the Vietnamese market. Our customers come to us and share their current pain points and expectations for the future. Understanding their needs, solving the problem, and sensing their trust, CJ Gemadept has been gradually improving the quality of retail logistics services through a pioneering chain of solutions, applying advanced and efficient information technology. If someone thinks that retail is an art, then retail supply chain workers must be artists themselves. These true artists are skilled in mixing, arranging, and solving all the tricky problems of retailing in a smooth, logical, and scientific way!

Returning to retail logistics today, we are honored and proud to introduce our customers and partners to the Pick To Light solution combined with Automatic Conveyor - a specialized and pioneering operating model successfully implemented by CJ Gemadept for the retail industry in Vietnam.

*** What is Pick to Light?

Pick to Light (PTL), also known as Digital Picking System (DPS), is a technology that processes orders according to light module instructions. The pickers only need to move to the picking positions with the illuminated signals and take the displayed amount accurately. This helps minimize the picking process, saves time in determining the location of the picking items, and creates favorable conditions for the operators to perform operations quickly. Pick To Light also allows warehouse employees to truly experience a "free hands" and paperless operation process. Searching for products and picking items has perhaps never been as simple and easy as this!

To fully exploit the potential of the Pick To Light system, we combine the implementation of parallel solutions such as Automatic Conveyor, providing a seamless and highly efficient operation for our customers:

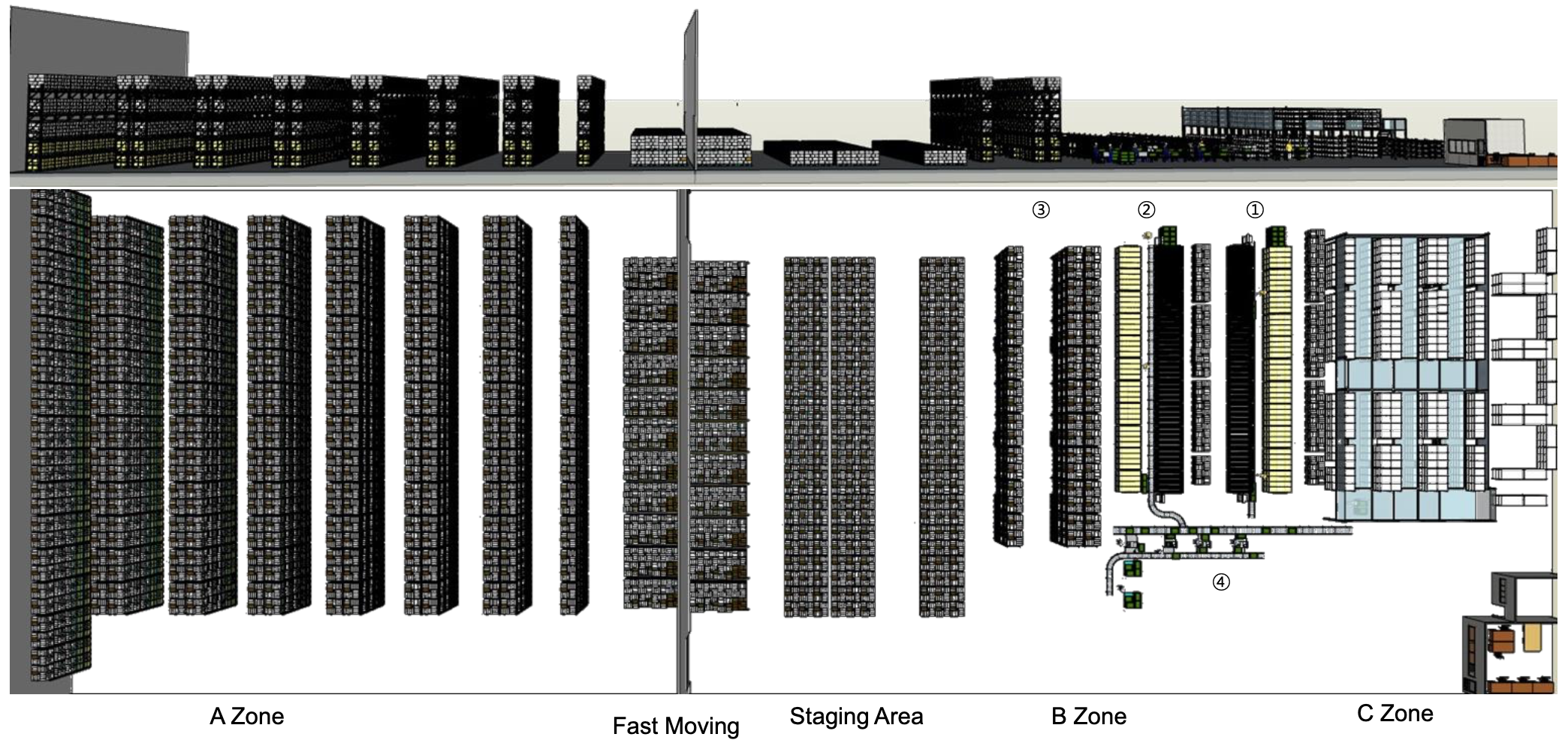

1. Optimization of operations through specialized layouts:

The layout for retail warehouses is truly different compared to FMCG, furniture, foreign goods, etc. Many items with different sizes, units of import and export, and throughput speeds lead to the need to divide and specifically define functional areas in the warehouse, including:

Inbound Staging area

Storage area

Pick-face area for Fast-moving goods in full boxes

Pick-face area for Fast-moving goods in individual units

Pick-face area for Normal & Slow-moving goods in individual units

Inspection area

Outbound Staging area

Designing, dividing, and specifically defining the functions of areas in retail warehouses is carried out through ABC Analysis. Specialized layouts combined with uniform operation processes will help import and export operations become efficient and smooth.

2. Apply RF Scanners to all operational stages:

All incoming and outgoing products are scanned with barcodes and real-time managed on the Infor 11.5.1 WMS system. At the CJ Gemadept retail warehouse, goods are detailedly managed according to Pallet ID and Carton ID. The import and export processes require all operators to strictly comply with Scan IN, Scan Move, Scan OUT operations, helping to prevent and minimize human errors, update accurate data, and support measuring the productivity of workers.

3. Integration of Pick To Light and WMS systems:

The Pick To Light system helps increase productivity up to 20%. However, to achieve this figure, the exchange of data on orders, positions, and picking quantities must be continuous. The large number of order lines from stores placed high pressure on the Pick To Light-WMS integration flows and vice versa, requiring them to truly be smooth and ensure high load-bearing capacity. At CJ Gemadept, we easily handle this problem quickly and efficiently using the world's leading Integration Controller tool - ION.

4. Inspection solution combined with automatic conveyor:

The high productivity of Pick To Light inadvertently creates a need to accelerate the inspection area. The Inspection area needs to be optimized to achieve a balance speed compared to the picking area. Otherwise, the "bottleneck" problem is easy to occur and ultimately leads to ineffective operations of the entire chain. With years of experience in operating in the retail industry, we pioneered the pilot installation of an automatic conveyor to eliminate this bottleneck. Applying the automatic conveyor helps the picking and counting staff save time on moving. Through the sensor system, goods after picking are automatically regulated to the inspection area. All operational stages are combined continuously, smoothly, and effectively.

5. Solutions for managing toteboxes and tools for new store openings

Toteboxes are a familiar concept in retail warehouses. A large number of small items require packaging and sealing before being shipped out. Alongside managing goods, it is also important to track and trace empty toteboxes (or individual packages) accurately. The inventory of empty toteboxes at the warehouse and stores must be managed and monitored to ensure that the circulation process does not cause any loss of quantity. In addition, the strategy for opening new stores creates a need for timely management and supply of tools and equipment outside the list of sales products, such as cash registers, tape, plastic bags, storage racks, etc. All of these issues are addressed in the comprehensive service package of CJ Gemadept logistics. With years of experience in the industry, standardized operating procedures, and support from the WMS Infor 11.5.1 management system, we are confident in optimizing this problem with competitive costs for customers.

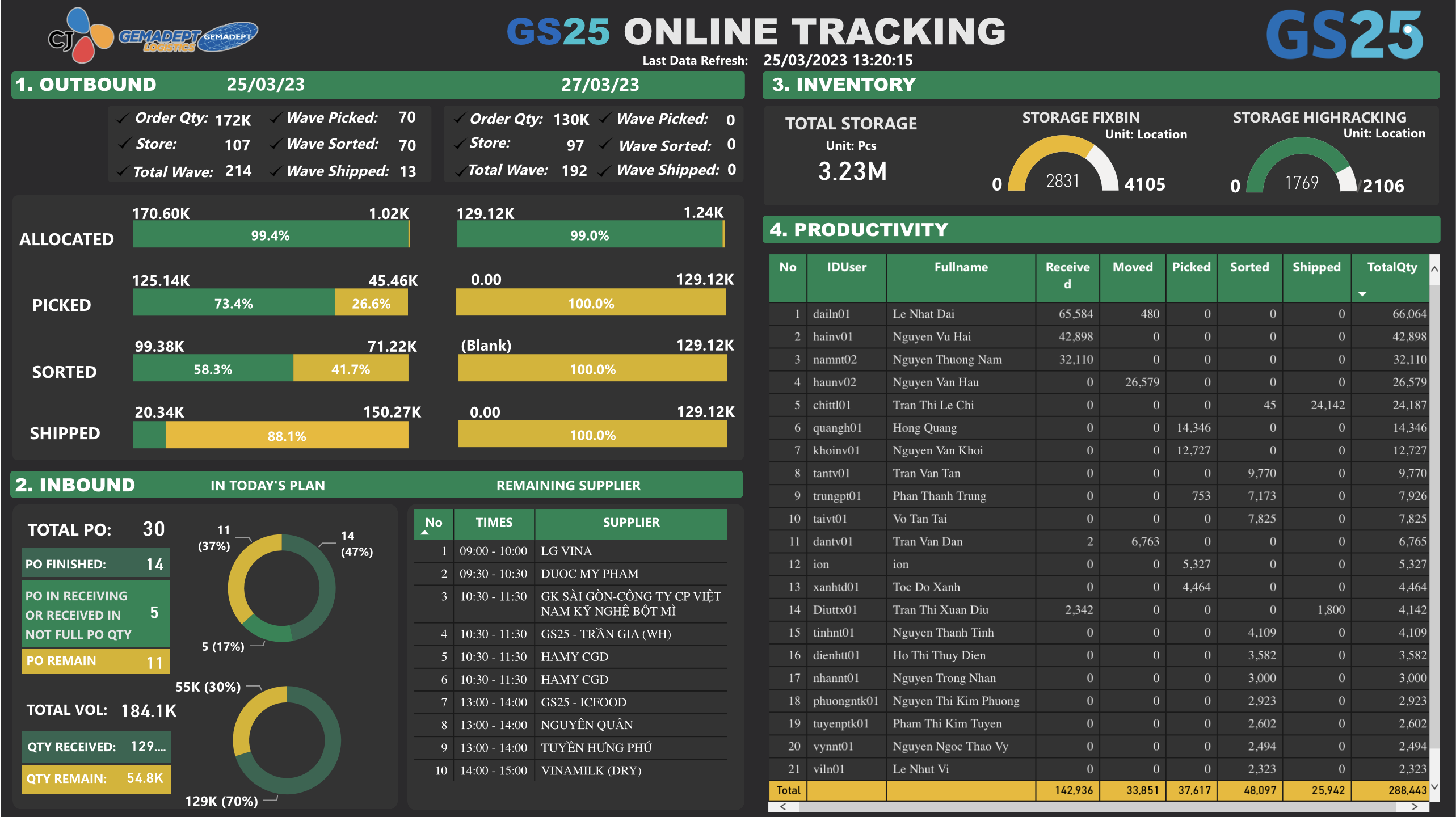

6. "Visualize" operations with an intuitive Dashboard system, accessible through multiple devices.

The large volume of retail orders, big and small, makes traditional tracking and decision-making methods with high latency (Excel, Report, Email) no longer suitable. At CJ Gemadept, we provide intuitive Dashboard solutions, with real-time updated data, designed specifically for each customer. Through the ability to access on multiple devices (PC/Laptop/Smartphone/Tablet), and multiple platforms (Web/Window/IOS/Android), capturing information about import/export status, inventory, and operating productivity becomes quick and extremely convenient.

The digitalization and automation story in logistics operations, in general, and retail warehouse operations in Vietnam, in particular, are always a concern and long-term goal of CJ Gemadept Logistics. "Opening the way," "Doing the best," "Have to be better" - these are three of our core cultural values. Come and share your logistics story with us, share with us the pain and difficulties in your warehouse operations. CJ Gemadept commits to accompany and help you solve those "chronic headaches" with a differentiated comprehensive logistics service.

You come, We serve!

Source:

Solution Department - CJ Gemadept Logistics