CJ Gemadept is proud to announce the successful completion of the process improvement consulting service and the upgrade of the Warehouse Management System (WMS) for Mekong Logistics (MKL), a member company within the Gemadept ecosystem. Mekong Logistics offers comprehensive logistics services with a state-of-the-art cold storage system that meets international standards, ensuring stable temperatures and food safety for the entire Mekong Delta region.

Mekong Logistics Warehouse

Upon receiving the project brief, CJ GMD's team of experts immediately began analyzing the requirements and assessing the project's situation. Beyond the primary objective of upgrading the WMS software, the team identified key pain points and bottlenecks that needed to be addressed:

-

Old WMS Version: MKL was using an outdated WMS version that required integration with various third-party software developed by external vendors. This not only complicated the process but also made it difficult to maintain operational consistency.

-

Limited Scalability: The current WMS version limited the ability to scale and meet MKL's growing operational demands.

-

High Maintenance Costs: Maintaining and developing the existing system incurred significant costs, impacting business efficiency.

-

Lack of Direct Support from the Software Provider: With the outdated WMS version, MKL received minimal support from the software provider, making it challenging to resolve issues or update the software.

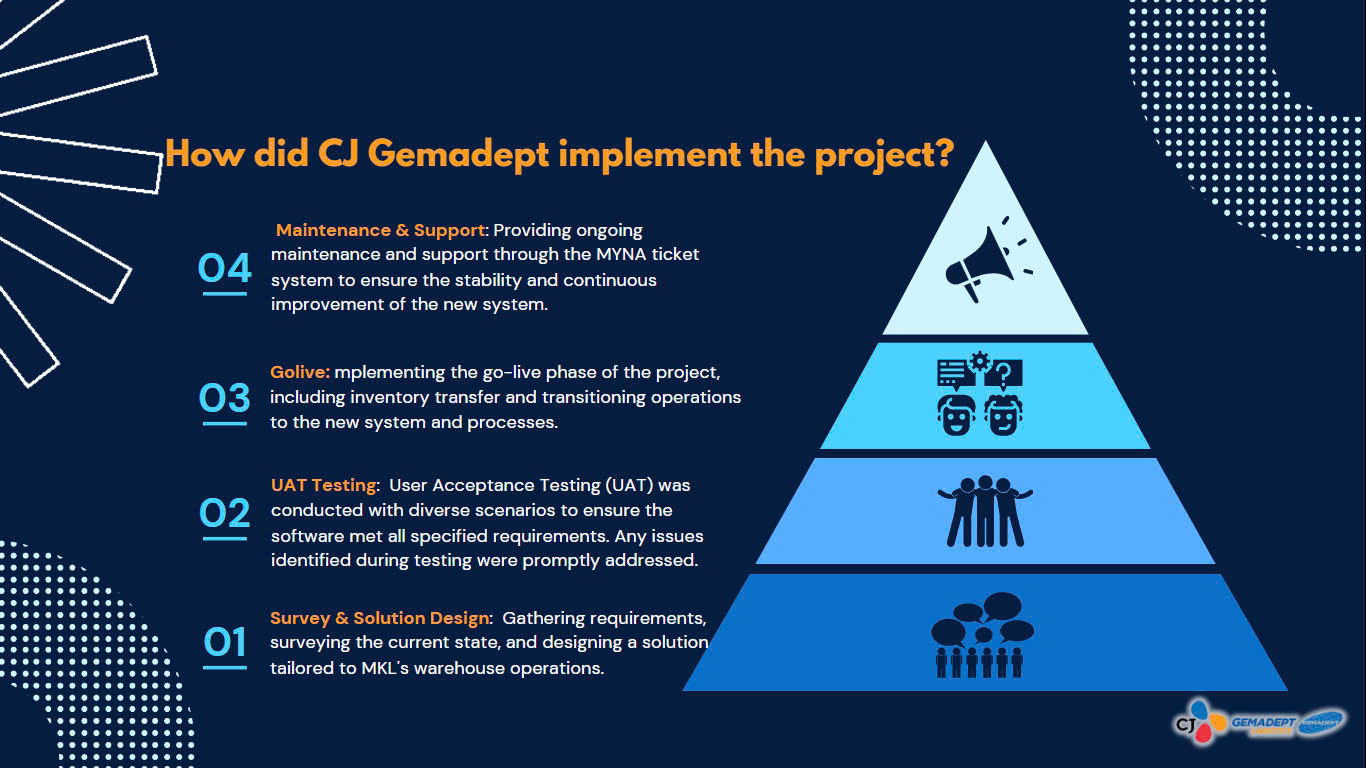

The project was divided into three phases:

Project Implementation Process for Mekong Logistics

-

Phase 1 – Survey & Solution Design: Gathering requirements, surveying the current state, and designing a solution tailored to MKL's warehouse operations.

-

Phase 2 – UAT Testing: User Acceptance Testing (UAT) was conducted with diverse scenarios to ensure the software met all specified requirements. Any issues identified during testing were promptly addressed.

-

Phase 3 – Go-Live: Implementing the go-live phase of the project, including inventory transfer and transitioning operations to the new system and processes.

Breakthrough Achievements in the WMS Upgrade Project at Mekong Logistics:

-

Successfully completed the transition of 100% of the inventory and system characteristics from Infor version 10.4 to the advanced version 11.5.1, ensuring absolute accuracy and perfect synchronization.

-

Designed and implemented a completely new receiving process using modern RF Mobile devices provided by CJ Gemadept, significantly reducing receiving time via QR Code and greatly enhancing accuracy (IRA) in warehouse operations.

-

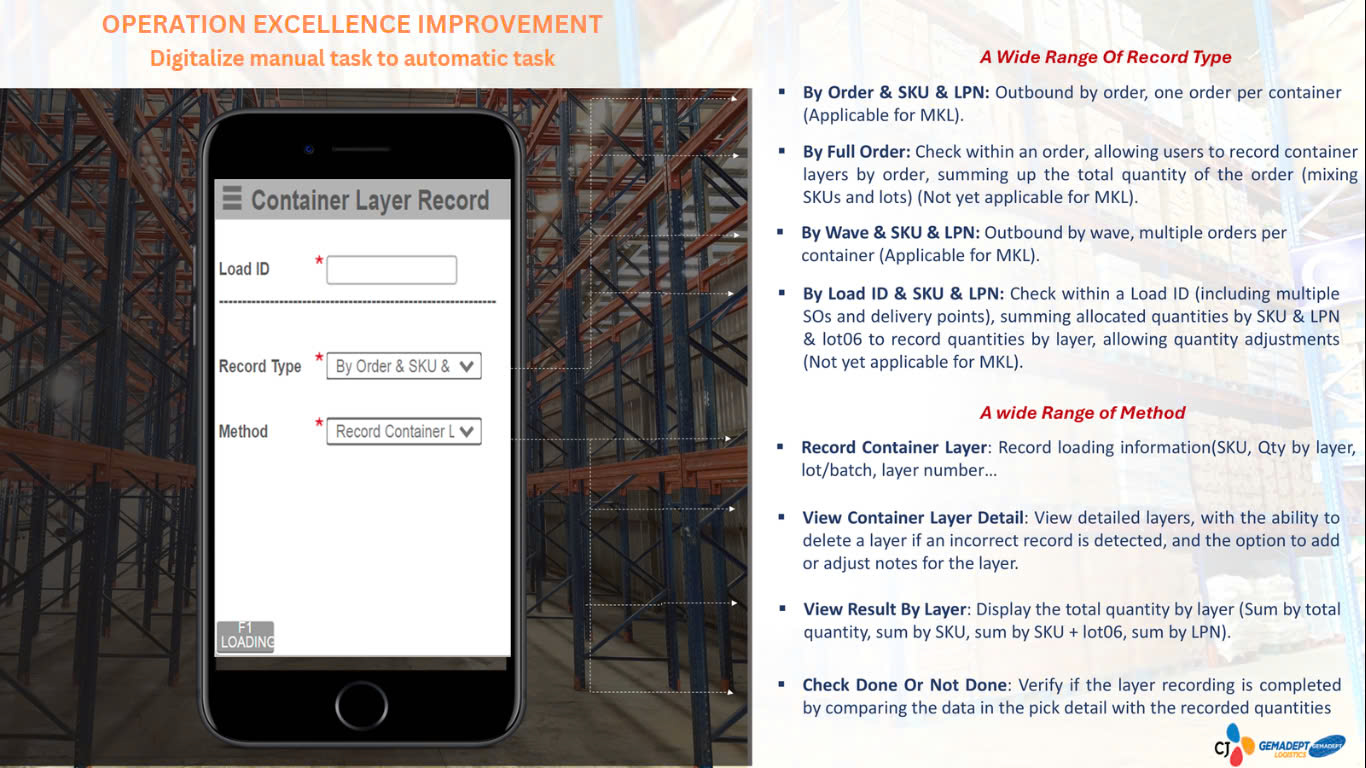

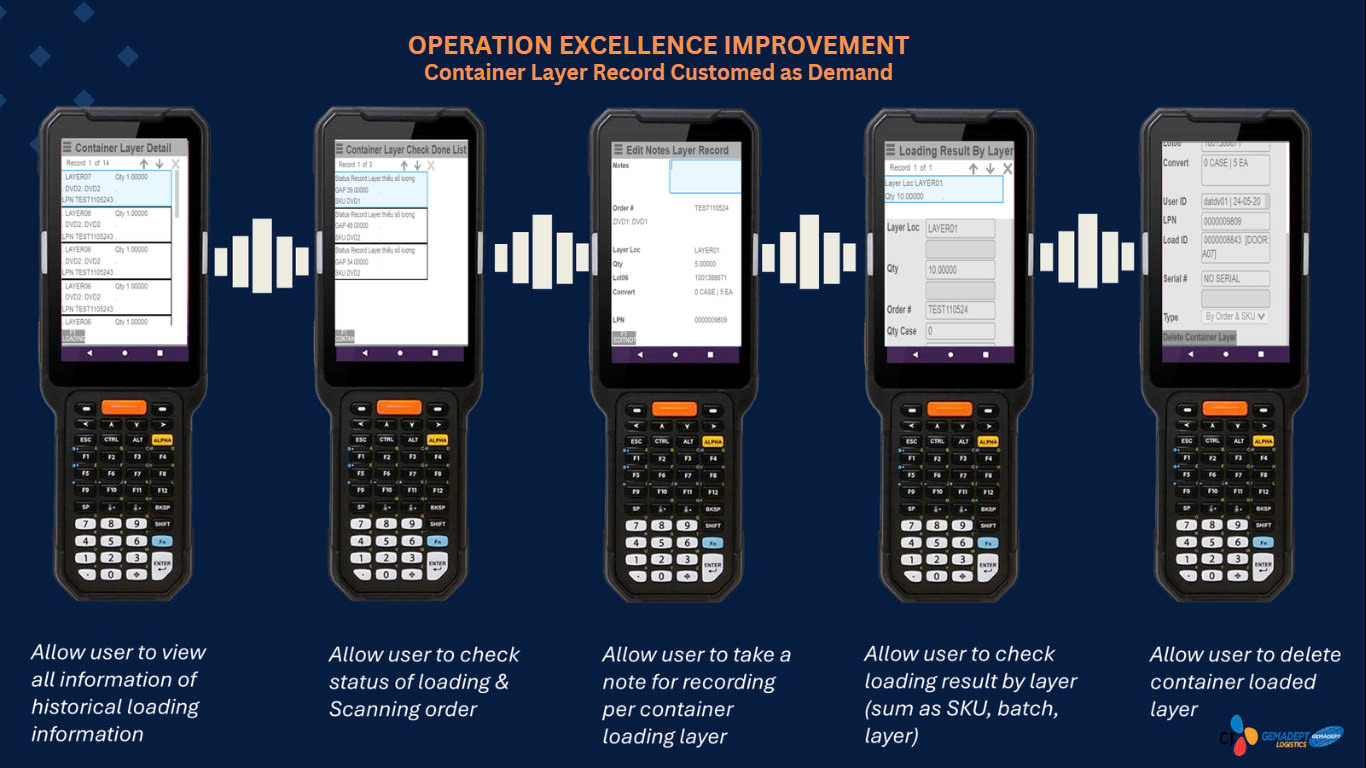

Introduced a pioneering solution for recording Loading in Containers during the export phase, digitizing operations from manual recording to system-based logging (PDA devices).

CJ GMD launches the first Container Layer Record solution at Mekong Logistics warehouse.

-

Implemented a flexible dispatch solution on RF devices, customized to the unique needs of users, with integrated smart alerts to detect discrepancies during operations.

-

Optimized the system by eliminating vendor-supported WMS add-on software, reducing costs, and enhancing system efficiency.

-

Comprehensively completed the training and provision of detailed guidance materials, enabling Mekong Logistics' team to master and effectively operate the new WMS system.

With dedication and extensive experience in warehouse system implementation, CJ Gemadept has not only completed but also exceeded expectations in the WMS upgrade project at Mekong Logistics. The advanced solutions, perfect synchronization, and superior efficiency have positioned Mekong Logistics to face any challenges and seize new opportunities in the cold storage logistics industry. CJ GMD is proud of this successful collaboration and remains committed to supporting Mekong Logistics on their journey toward sustainable development.